We recommend, cleaning and servicing thoroughly RSC Suspensions products at regular time intervals, but at least twice a year, as follows:

- Evaporate the M52 thread oft he shock absorber and spring plate threaded sleeves with a hot steam cleaner.

- Thereafter, blow the M52 thread of the shock absorber and spring plate threaded sleeves dry thoroughly with compressed air.

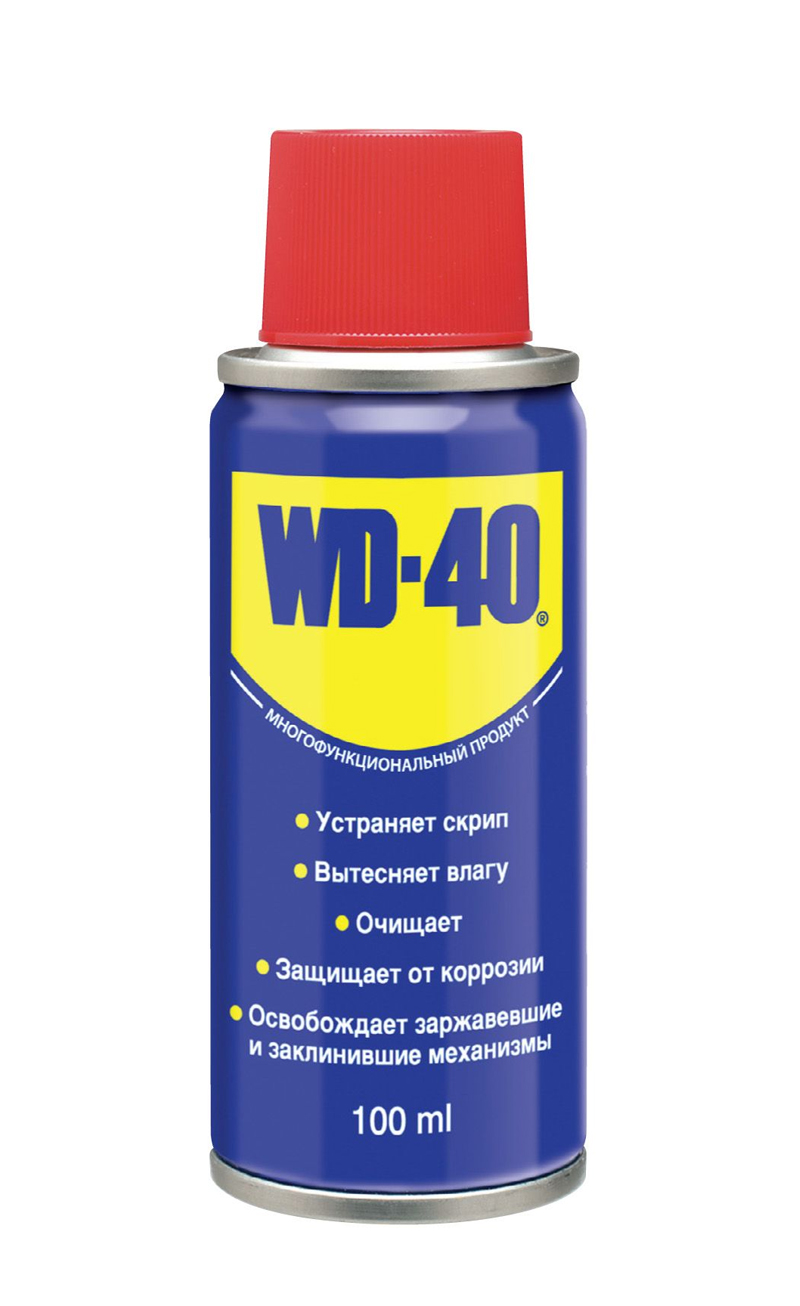

- Spray the threaded surfaces lightly with WD-40 Classic (1 tin 25ml included in the delivery scope).

- Clean the spherical bearing with an impregnated cloth with regular brake cleaner and blow it out with compressed air.

- Spray the spherical bearing and rubber bearings lightly with WD-40 Classic (1 tin 25ml included in the delivery scope).

- Check for tightness the lock nuts of the spring plate and the lock nuts on the coilover and lower shock mount (brackets).

- Check the allen screws of the camber plate for tight fit.

- Check the nuts of the piston rods for tight fit.

- Check the allen screws of the stabilizer holder for tight fit.

- Check the adjustable stabilizer rods for tight fit.

- Check the hardness adjustment of the damper by single clicking forward and back for ease of movement.

Note:

All RSC coilover parts may show paint damage and corrosion during the warranty period. When operating in regions with extreme environmental conditions (high salinity, for example, near the coast and / or increased winter operation by gravel and road salt), the RSC coilover parts are exposed to many times higher loads, which can be seen in premature paint loss and corrosion. It is therefore advisable to clean or evaporate the RSC coilover parts as well as possible in such regions with every car wash. The functions of the RSC coilover parts are not impaired in their function in case of paint damage and corrosion. Paint damage and corrosion are no guarantee.

RSC Suspensions recommends WD-40 Classic in the 100 ml can